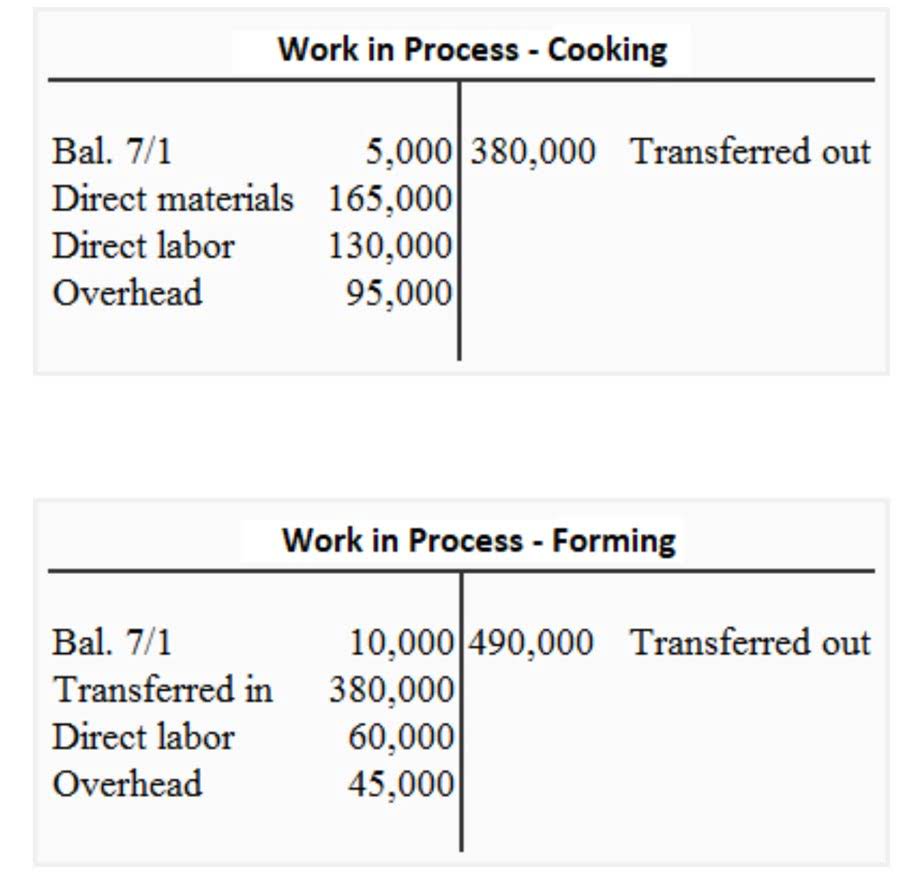

That is, a predetermined overhead rate includes the ratio of the estimated overhead costs for the year to the estimated level predetermined overhead rate of activity for the year. To calculate the predetermined overhead rate of a product, a business must first estimate its level of activity or units to be produced. Instead of using the numbers of units to be produced, the business may also choose another activity base such as labor hours or machine hours that are needed to meet the estimated level of activity. The company estimates that 4,000 direct labors hours will be worked in the forthcoming year. Commonly, the manufacturing overhead cost for machine hours can be ascertained from the predetermined overhead rate in the manufacturing industry.

Estimated Total Manufacturing Overhead Costs

You can envision the potential problems in creating an overhead allocation rate within these circumstances. As you’ve learned, understanding the cost needed to manufacture a product is critical to making many management decisions (Figure 6.2). Knowing the total and component costs of the product is necessary for price setting and for measuring the efficiency and effectiveness of the organization. Remember that product costs consist of direct materials, direct labor, and manufacturing overhead. A company’s manufacturing overhead costs are all costs other than direct material, direct labor, or selling and administrative costs.

- This rate is frequently used to assist in closing the books more quickly, since it avoids the compilation of actual manufacturing overhead costs as part of the period-end closing process.

- Suppose following are the details regarding indirect expenses of the business.

- This means that for every dollar of direct labor cost a production process uses, it will use $1.50 of overhead costs.

- The activity base for applying manufacturing overhead is normally a unit quantity which relates to the manufacturing process such as the following.

- Remember, even a rough predetermined rate is better than ignoring overhead entirely, which is a common mistake that leads to underpricing and cash flow problems.

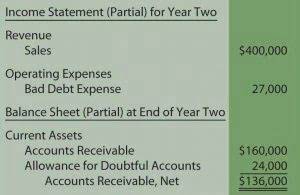

Sales

- The company actually had $300,000 in total manufacturing overhead costs for the year, and the actual machine hours used were 53,000.

- Once you have a good handle on all the costs involved, you can begin to estimate how much these costs will total in the upcoming year.

- Suppose that X limited produces a product X and uses labor hours to assign the manufacturing overhead cost.

- This option is best if you’re just starting out and don’t have any historical data to work with.

- Now ABC Co. can compare its estimated results with actual results to evaluate how it has performed.

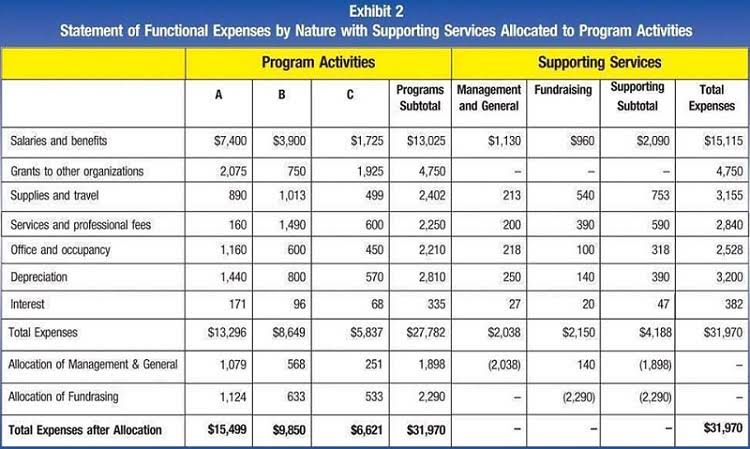

This aids data-driven decision making around overhead rates even for off-site owners and managers. Built-in analytics help uncover spending trends and quickly flag unusual variances for further investigation. Analyzing overhead rates by department in this manner helps identify problem areas and opportunities to improve profitability. If the actual overhead at the end of the accounting period is 1,575 the overhead is said to be under applied by 125 (1,450 – 1,575). If the actual overhead at the end of the accounting period is 1,575 the overhead is said to be over applied by CARES Act 25 (1,600 – 1,575). Again the actual overhead at the end of the accounting period is 1,575 and the overhead is said to be under applied by 81 (1,494 – 1,575) as shown below.

Materials Cost Example

These Sources include White Papers, Government Information & Data, Original Reporting and Interviews from Industry Experts. Learn more about the standards we follow in producing Accurate, Unbiased and Researched Content in our editorial policy. Learn about emerging trends and how staffing agencies can help you secure top accounting jobs of the future. STR can be used to measure the success of a product, track trends, and compare sales across different channels or…

Calculating Manufacturing Overhead Cost for an Individual Job

While predetermined overhead rates are widely used and needed for businesses, they may have some limitations. A business needs to estimate its total overheads for a period and estimate its total units or activity basis for the predetermined overhead rates. If these estimates are not accurate, they can end up causing a lot of problems for the business specially if decisions are based on the rates, such as pricing decisions. Although not directly related to a specific product or service, indirect costs are still paramount in decision-making.

Managerial Accounting

For most small to medium businesses, categorizing overhead into 5-10 major categories (rent, utilities, indirect labor, etc.) is sufficient. Larger operations might break this down further into categories for better tracking and control. Using last year’s overhead rate without considering changes can lead to pricing mistakes. If there are no significant changes, the Predetermined Overhead Rate will be kept for use in the following year.

For example, if we choose the labor hours to be the basis then we will multiply the rate by the direct labor hours in each task during the manufacturing process. Now management can estimate how much overhead will be required for upcoming work or even competitive bids. The predetermined rate is also used for preparing Online Bookkeeping budgets and estimating jobs costs for future projects. A predetermined overhead rate is used by businesses to absorb the indirect cost in the cost card of the business.